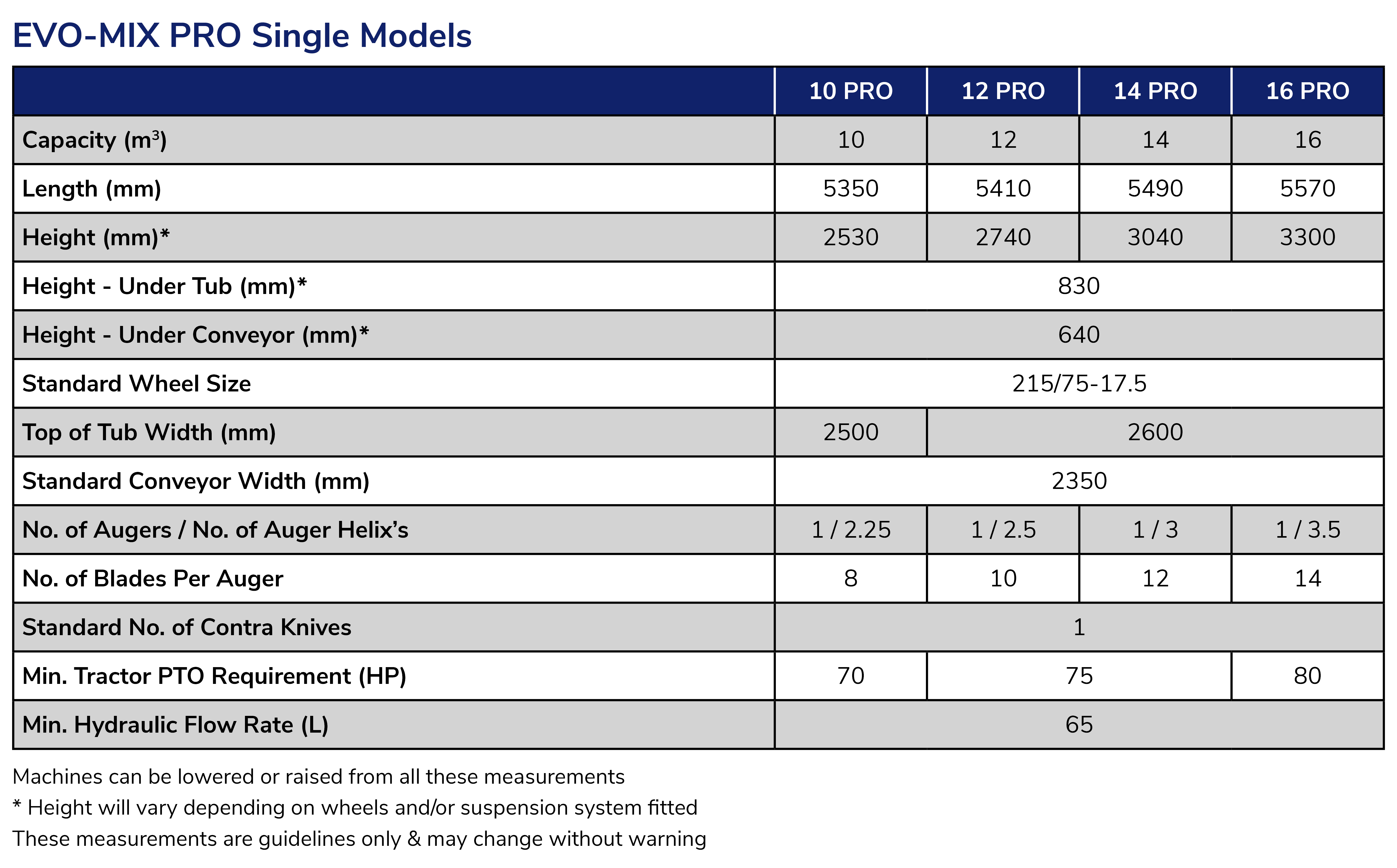

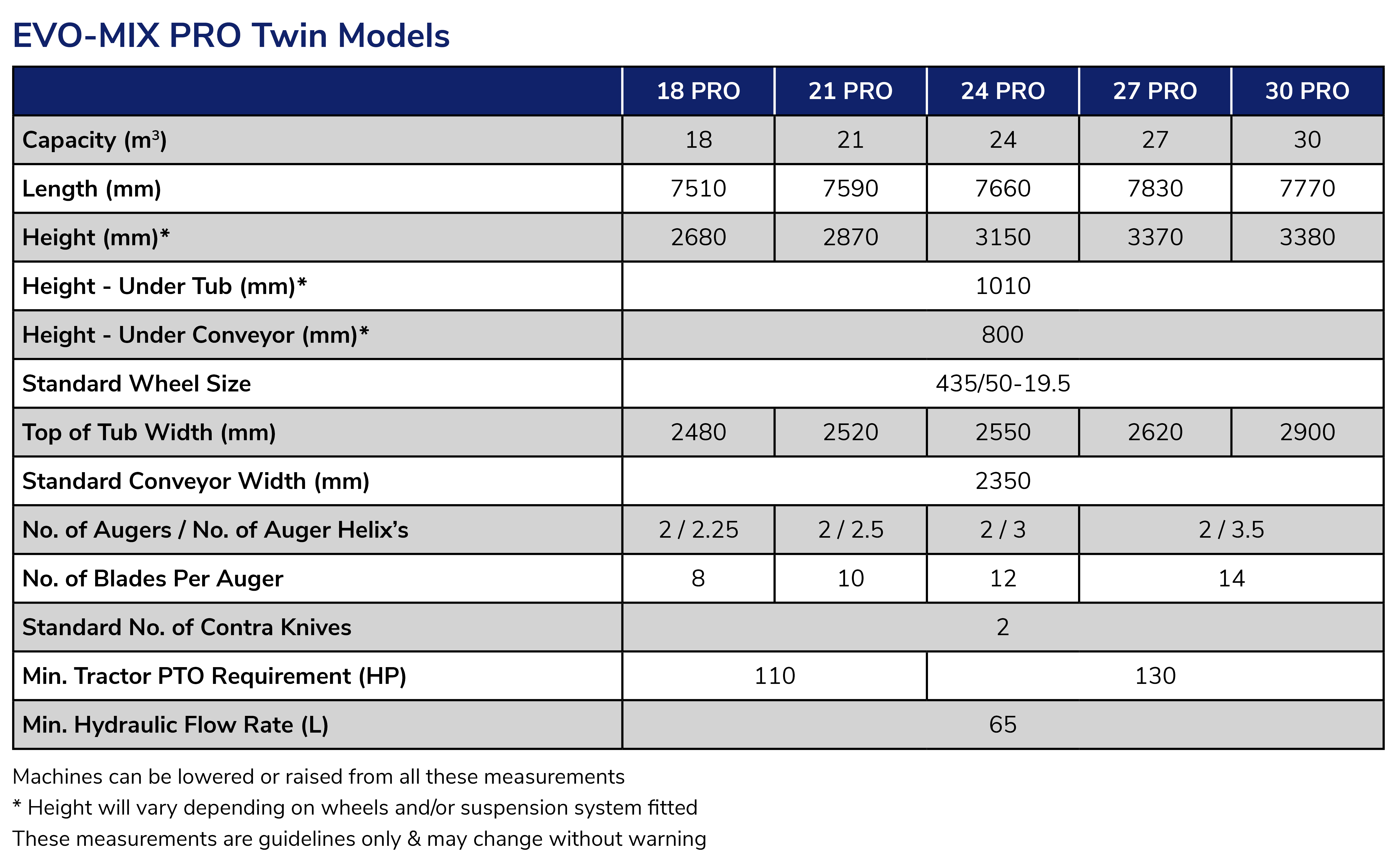

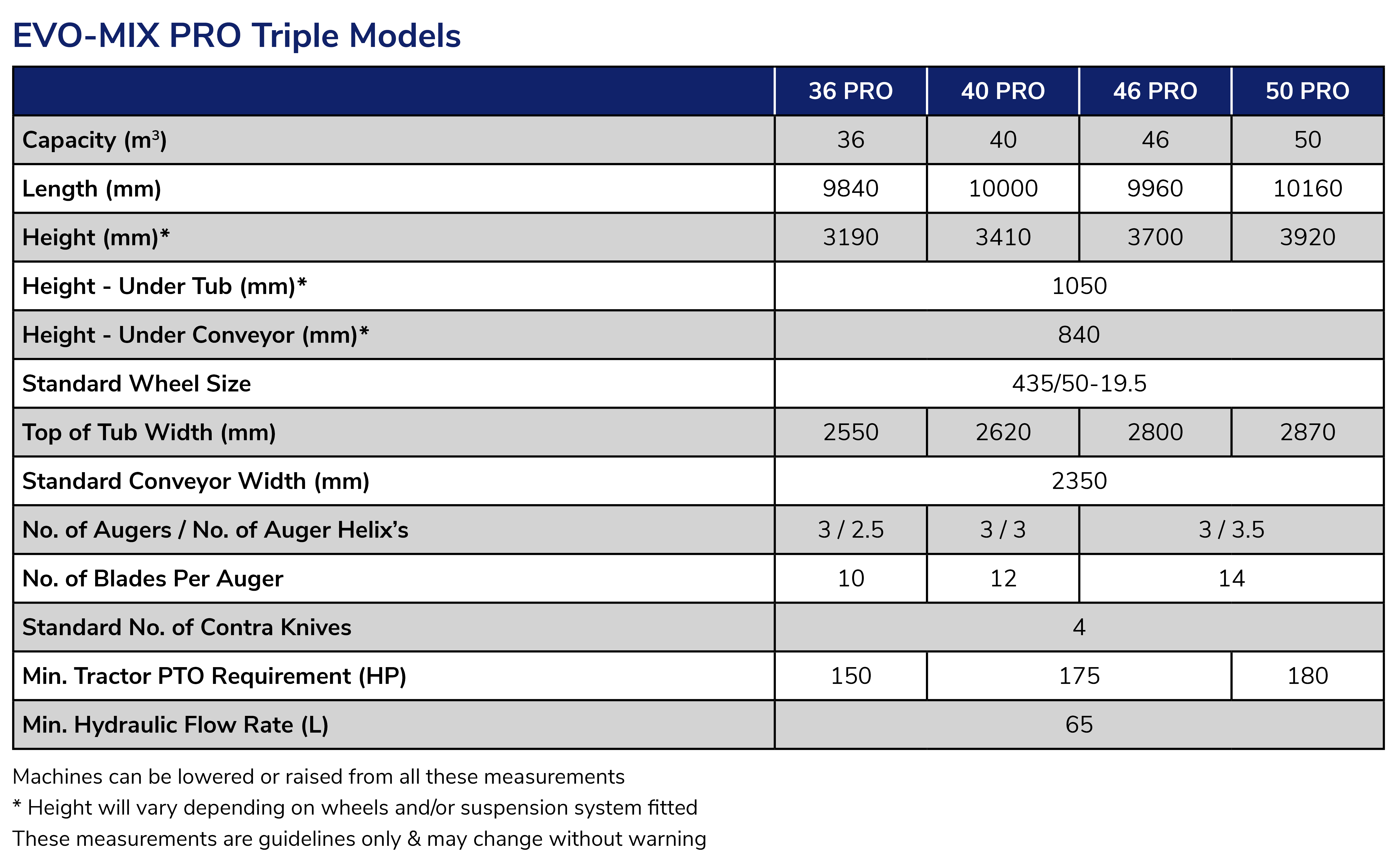

After listening to the UK market requirements, we redesigned the EVO-MIX machine to allow us to stay ahead of the competition. Improved in every area possible, the EVO-MIX PRO can deal with even the harshest environments. Never skipping a beat, it gives you the needed reliability in a diet feeder. EVO-MIX PRO ranges from 10-50m³, and is available in three different models – single, twin & triple.

Designed in the UK and built to a high specification using the highest quality materials, each machine is specified and built to suit each individual customer requirements.